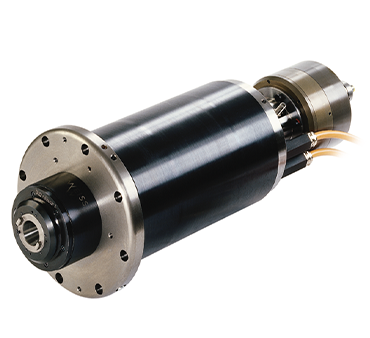

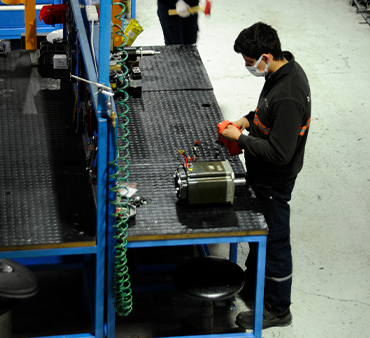

SPINDLE MAINTENANCE REPAIR SERVICE

Sİ-MUT Technical; It offers fast and quality service thanks to its tested processes using its long years of spindle repair experience. The repaired Electrospindle and externally driven spindles are technically at the level of the original product.

Original spare parts are used during the Spindle repair and the most economical solution is always offered to the customer. Our customer's business urgency constitutes our main philosophy at all stages of repair and renovation.

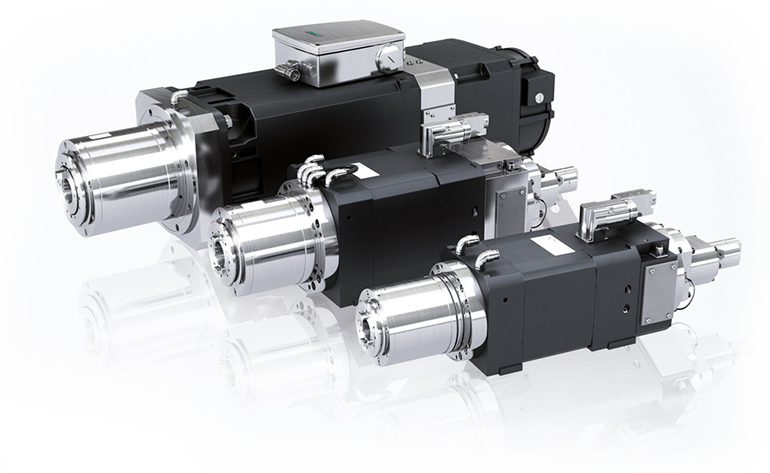

WEISS SPINDLE SERVICE

*SI-MUT Teknik, the authorized service of SIEMENS WEISS Spindle, also provides service for all spindles currently available in the world market.

Why Sİ-MUT Teknik;

1. Quick Repair report and quote

2. Solution and repair as soon as possible,

3. Technically original product level,

4. Many years of experience experience.

Spindles that come for repair or refurbishment by our spindle specialist; It is pre-evaluated and recorded with a photograph in the "Spindle Tracking Program" specially developed for Sİ-MUT Teknik. Our service processes;

* Encoder system control,

* Stator winding control,

* Temperature sensor control

* Mechanical control,

* Tool holder blockage control,

* Tool holder control,

* Soğutma sistemi kontrolü,

* Lubrication system control,

* After disassembly, fault diagnosis is carried out by detecting damaged parts.